What Does "Backordered" Mean? Definition, Examples & Tips

Dealing with backorder situations can often be a frustrating experience for both retailers and their customers.

Imagine that you see the perfect product online, add it to your cart, and eagerly await its arrival.

But then, instead of receiving your new purchase by the estimated arrival time, you get a notification that delivery will take longer than expected due to backorder issues.

While it’s understandable that sometimes items go out of stock (OOS), it can be unpleasant for customers to have to wait even longer for something they’ve already paid for.

Backorders happen when you least expect it, whether we’re talking about an unexpected discontinued production, high demand, low safety stock point, or increased supplier lead time.

What does backordered actually mean?

To put it simply, “backordered” means that a product is not available at the moment of purchase but is expected to be shipped by a particular date. It is not unusual for merchants to sell backordered products, shipping them out once they’ve replenished their inventory.

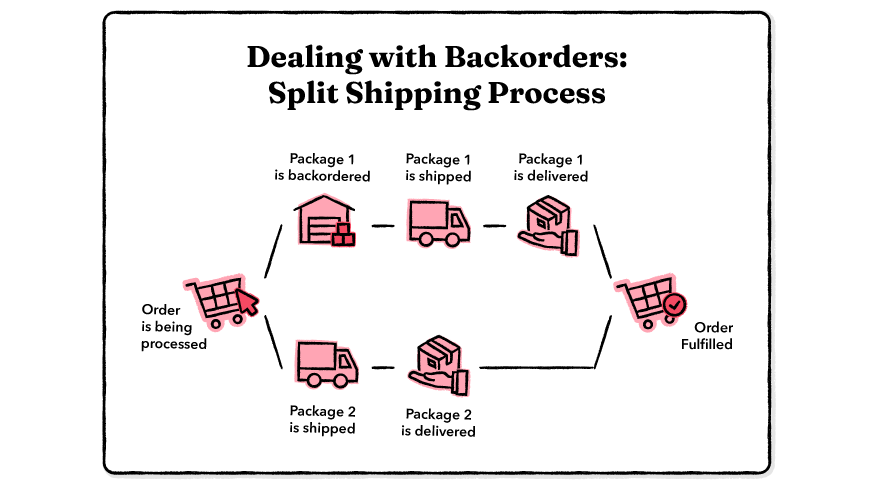

If other items in the same order are in stock, the shipment may be split and sent out at different times. The products that are on backorder will be shipped at a later date.

For customers, it’s easy to miss a delivery because they weren’t even aware of the fact that there were multiple packages they should’ve been expecting. This is why it’s important to keep customers informed about the whereabouts of their split order using order tracking tools and delivery notifications.

Backordered Products Vs. Out-Of-Stock Items

If a product is backordered, it means that the item will be available to purchase in the near future. In this case, the seller can fulfill a purchase order, although it might take longer than usual. Merchants usually provide an estimated shipping date to set the right expectations.

On the other hand, when a product is out of stock, it’s not available to purchase at the moment and there’s no estimated delivery date.

Think of it this way:

Normally, when the item is out of stock, you might state if a product is unavailable permanently or temporarily on the product page and provide visitors with alternatives.

However, when you’re dealing with backorders, you might enable customers to pre-order items and provide them with an estimated date for shipping (e.g., Available for shipping in 14 business days)

What are the most common reasons for backorders?

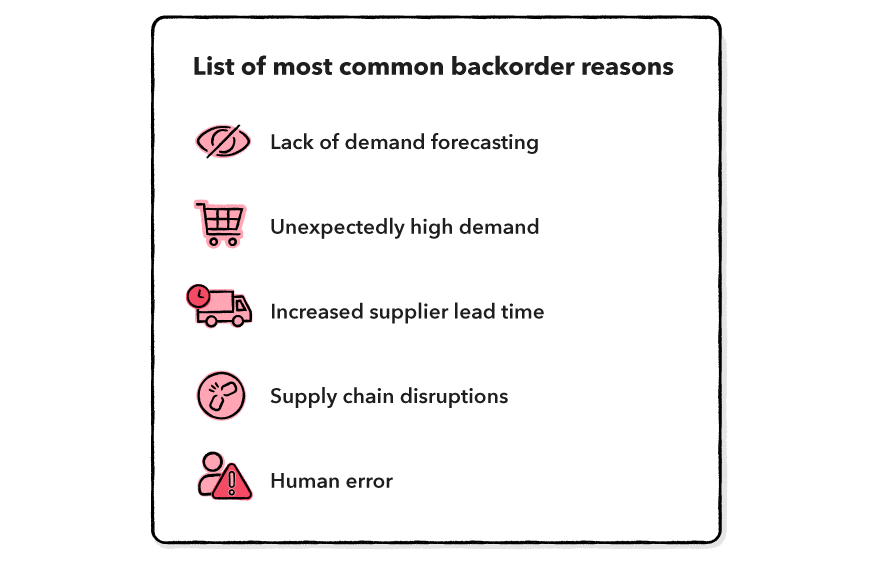

Poor demand forecasting, unexpected demand that exceeds supply, increased supplier lead time, and overall supply chain bottlenecks, including delivery exceptions like weather, customs regulations, and even human error.

Luckily, most of these can be avoided or reduced using the right tools, having clear procedures in place, keeping an eye on inventory and warehouse management, and communicating efficiently with suppliers but also with customers.

For instance, if you want to manage your warehouses more efficiently, track performance and lead time using tools like WeSupply Logistics Analytics to see what’s not working and where you can improve the processing time and even optimize your routes.

Are backorders bad for your business?

You might be wondering “Are backorders bad for your business?“

As with most things in life, the answer to this question is “It depends.“

Constantly dealing with backorder issues might cost your business if you’re not communicating openly and honestly with your customers, letting them know in advance that their order delivery will take longer than initially planned.

On the bright side, backorders can be a sign that you’re in high demand. If you’re also running out of stock, it means that people are interested in what you’re selling. That’s a good problem to have!

In the end, backorders are “bad” for your business if they’re the root cause of your reduced average order value and customer lifetime value or the increase in cart abandonment rate and the number of canceled orders.

It’s important to ask yourself:

- Is this putting my business and my loyal customers in a bind?

- Is this adding additional pressure on my employees?

- Is this affecting my ROI and long-term business growth?

If so, you might consider investing in a delivery notification tool that provides real-time updates that build excitement, ease post-purchase anxiety, and reduce the number of canceled orders and refund requests due to OOS situations and stalled shipments.

How long do backorders usually take?

How long will the backorder take to fill?

Once again, it depends on the manufacturer, supplier, the company, and the product itself.

On average, it takes between 14 and 21 days to fulfill a backorder. In some cases, it can take even longer than that.

If it’s a matter of only a few days, customers will most certainly be patient. But if it takes weeks or months, they’re more likely to cancel their order.

On the other hand, as long as need to communicate with your customer from start to finish so they are aware of the situation, you’ll be able to reduce the chances of them canceling their order.

How to deal with backordered items?

As a retailer, you know that backordered items are sometimes inevitable. However, dealing with them doesn’t have to be a nightmare. Here are a few tips for handling backordered items to minimize the inconvenience for customers:

- Forecast customer demand to make sure you always have some safety stock items available in at least one and up to several locations.

- Reduce supplier lead time or work with several different suppliers to cover the unexpectedly high demand.

- Send shipping delay notifications via email and/or SMS as soon as the problem is discovered to set customer expectations.

- Offer a discount coupon to make up for the backordered situation, directly on the order tracking page, once the order has shipped.

- Include a freebie or other promotional item with the backordered shipment to show customers that their patience is appreciated.

By taking some of these steps and being proactive in terms of communication, retailers can turn any backorder situation from a headache into an opportunity to build customer loyalty.

What to do when customer demand exceeds supply?

Make sure you have adequate safety stock levels.

Keep a minimum quantity in your physical stores, warehouses, or distribution centers. Make sure you constantly monitor stock levels in order to be able to cover unusual demand so that these situations won’t have a negative impact on customer loyalty.

Invest in a supply chain & inventory management system.

Especially if you’re working with several suppliers, try to invest in supply chain and inventory management software. This way you’ll be able to track orders more efficiently, identify delayed deliveries, and proactively communicate with your customer base.

Make sure you plan ahead for returns as well.

Backorders or not, returns are still part of any retail business. And you need to be particularly prepared when the demand exceeds your supply. That can also mean a higher volume of returns, refunds, and exchanges.

To make it easier for you and your team, you can always opt for a self-service returns management platform that enables you to automate most of your processes, generate return labels effortlessly, provide partial refunds if necessary, and encourage customers to initiate returns themselves, saving your customer care reps a significant number of tickets.

Enjoy the journey, despite the little obstacles you come across!

After all, it’s necessary to step back every once in a while and see how far you’ve come. Celebrate your progress and make the most out of these situations!

Why send proactive shipping delay notifications?

Truth be told, unless you have an efficient delivery notification system in place, contacting customers in a timely manner will make diminishing the chances of having the orders canceled much more difficult than it needs to be.

You’ve worked so hard to close the deal, secure the sale, and it’d be a pity to have your customers cancel due to a backorder.

That’s exactly why you need to send out proactive shipping delay notifications that reduce shipping anxiety and remove post-purchase dissonance. This ensures a positive customer experience, boosting customer loyalty and retention, and even improving customer lifetime value.

Moreover, you’ll be able to remove pressure from the customer support reps who are normally flooded with “Where is my order?” tickets on a daily basis, enabling them to use their time more productively.

Start using WeSupply to send out personalized, delivery exception email and SMS notifications, and have a better overview of stalled and split shipments!