Reverse Logistics: The Key to a Smooth Product Recall

Effective reverse logistics is crucial for a smooth product recall. This process manages the return of faulty items, helping businesses handle recalls efficiently and maintain customer trust. This article explores why reverse logistics the key to a smooth product recall is essential for successful recalls and shares strategies to optimize it.

Key Takeaways

-

Reverse logistics is essential for efficient product recalls, helping businesses manage returns, replacements, and safe disposal of defective products.

-

Swift execution of recalls protects consumer safety and brand reputation, relying on real-time data analysis and effective communication across the supply chain.

-

Optimizing reverse logistics not only reduces costs but enhances customer satisfaction and supports sustainability initiatives, making it a strategic advantage in crisis management.

Introduction: Why Reverse Logistics is the Backbone of Smooth Product Recalls

Reverse logistics has emerged as a key aspect in the complex world of supply chain management. Unlike traditional logistics, which focuses on the forward logistics movement of products from manufacturers to consumers, reverse logistics deals with the return journey. This reverse flow includes handling returns, replacements, and proper disposal of products. With the growing importance of reverse logistics, businesses are realizing that it plays a vital role in maintaining a smooth and efficient reverse supply chain, especially during product recalls.

When a product recall occurs, the stakes are incredibly high. Legal implications, financial losses, and the erosion of customer trust and brand reputation can all result from a poorly managed recall. Recalls often happen due to product defects, safety issues, or changes in regulations, making them an inevitable part of doing business.

Swift and efficient reverse logistics processes help manage recalls, reducing negative impacts on both the company and its customers.

Defining Reverse Logistics in the Context of Product Recalls

Reverse logistics involves moving products back through the supply chain for returns, replacements, or proper disposal. It involves a range of activities, including inventory management, transportation, and warehousing, all aimed at efficiently handling returned goods. In the context of product recalls, reverse logistics is responsible for retrieving defective products from consumers and ensuring they are either repaired, replaced, or disposed of safely.

Product recalls present one of the most complex challenges for reverse logistics management. Reverse logistics managers must coordinate the entire recall process, from identifying the affected products to managing their return and final disposition. This requires a well-orchestrated effort that includes data analysis, communication, and collaboration across the supply chain.

The right reverse logistics solution can make all the difference in executing a successful recall and maintaining customer trust.

The Business Case: How Effective Reverse Logistics Protects Profit and Reputation

Mitigating the financial impact of product recalls hinges on effective reverse logistics processes. By efficiently managing returns and recovering valuable assets, companies can minimize the costs associated with recalls and protect their profit margins. A well-executed reverse logistics process also bolsters brand reputation by showcasing a commitment to customer satisfaction and safety.

A smooth return process is crucial for improving customer satisfaction and loyalty. Enhances customer satisfaction and customer returns that are hassle-free are more likely to keep customers loyal and encourage repeat business.

Integrating reverse logistics with sustainable practices helps companies reduce environmental impact and attract environmentally conscious consumers. This not only boosts the company’s image but also contributes to a closed loop supply chain, where resources are reused and recycled, minimizing waste.

Step 1 – Identifying Affected Products: The Power of Data Analysis and Visibility

Identifying affected products quickly and accurately is the first step in managing a product recall. Real-time data analysis and visibility play vital roles in this process. Tools like Electronic Data Interchange (EDI), artificial intelligence (AI), and advanced analytics platforms help track shipped products and pinpoint which ones need to be recalled. This level of precision is essential for minimizing the scope of the recall and reducing associated costs.

Take, for example, the Rizo-Lopez cheese recall. Rapid identification of affected products through data analysis prevented further distribution and consumption, safeguarding consumers and the company’s reputation.

By using returns data to improve future product quality and design, companies can also prevent similar issues from arising, enhancing their overall product offerings and customer satisfaction.

Step 2 – Coordinating with Recipients: Streamlining Returns to the Right Destination

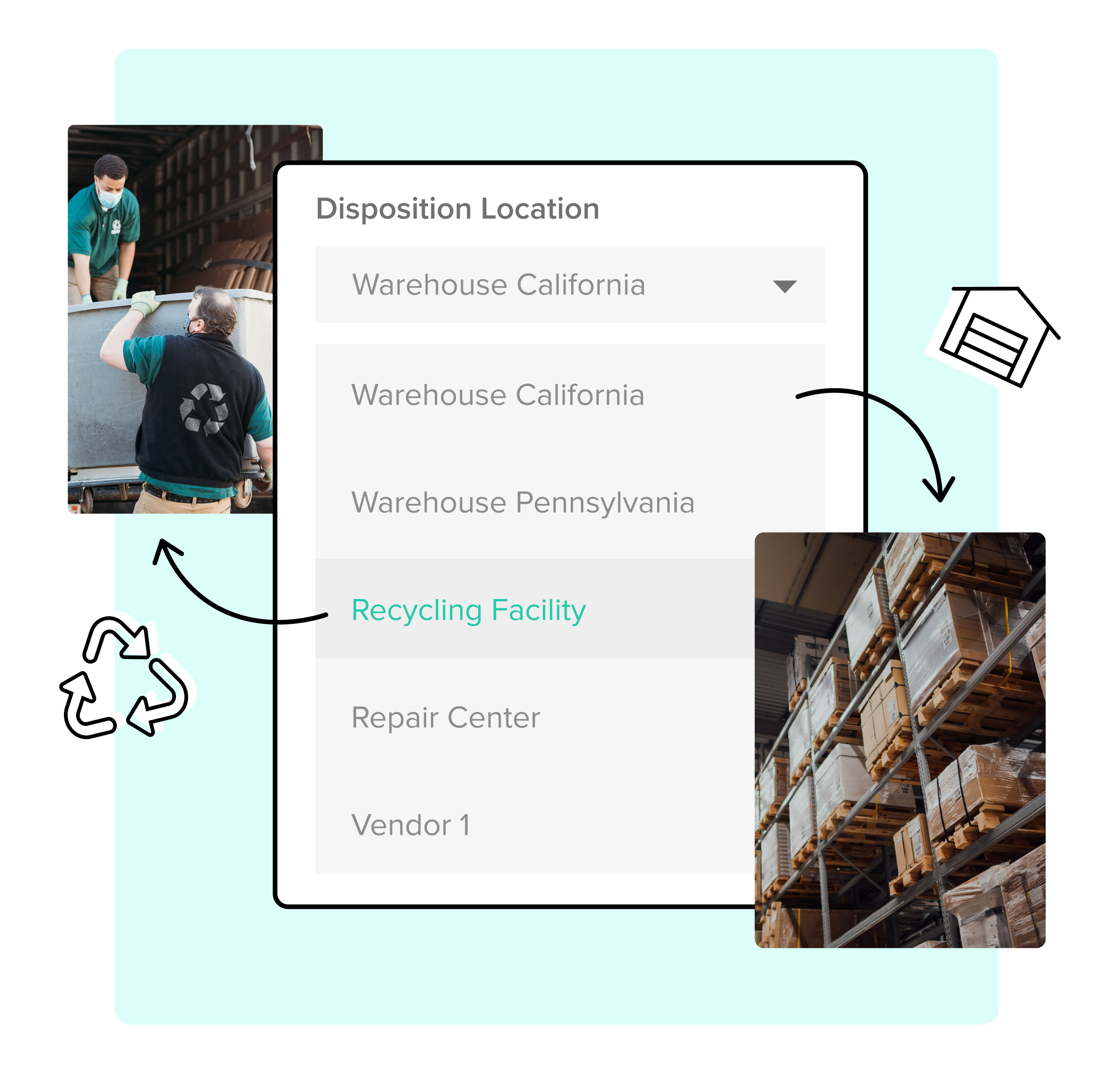

After identifying affected products, the next step involves coordinating their return to the appropriate recipient, whether it be a retailer, distributor, or manufacturer. This decision depends on factors such as speed, proximity, capacity, and the type of product being returned. Streamlining returns to the correct destination through effective reverse logistics minimizes delays and costs.

Collaboration across the supply chain is crucial for this process to work smoothly. Clear return policies help reduce confusion and ensure that all parties involved understand their roles and responsibilities. By establishing a centralized return center and using return authorization systems, companies can further optimize reverse logistics and enhance customer satisfaction.

Key Features:

-

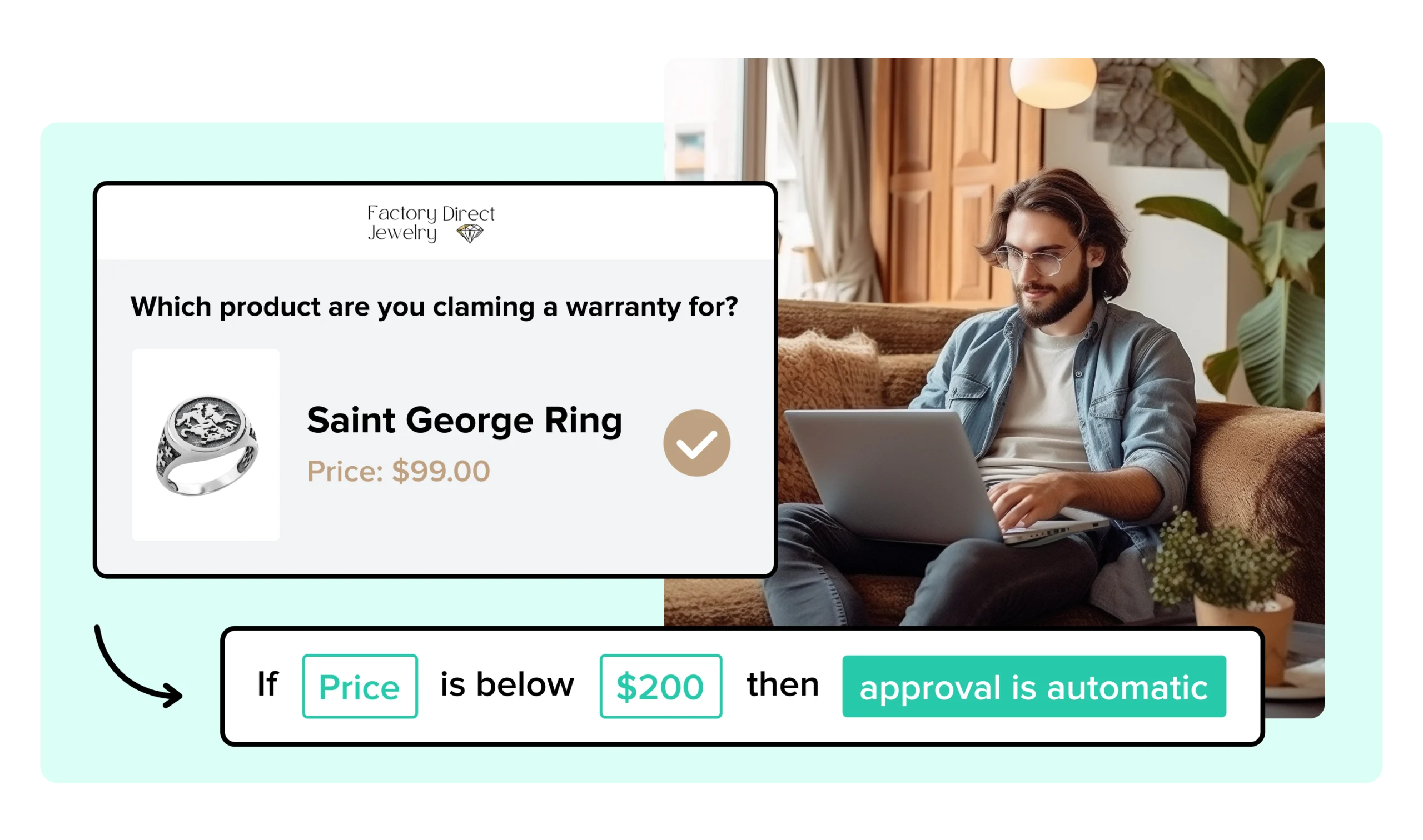

Automated Return Destinations:

-

Automatically route returned products to distribution centers, repair facilities, donation centers, or other predefined locations based on product condition and return reasons.

-

-

-

Provide a seamless, user-friendly return process with self-service options, fostering customer satisfaction and loyalty.

-

-

Cost Reduction in Reverse Logistics:

-

Minimize shipping and handling expenses by optimizing the return routing process.

-

-

-

Tailor return policies to specific conditions, ensuring efficient management of returns and compliance with business objectives.

-

Step 3 – Speed is Safety: Executing Recalls Quickly to Protect Consumers

Executing a product recall swiftly is crucial. Quick action prevents injuries, fatalities, and PR disasters, safeguarding consumer safety and maintaining customer trust. Multichannel communication, including recall letters, media alerts, and social media announcements, is essential for reaching a wide audience and ensuring that consumers are informed promptly.

Consider the case of Sauer Brands’ parsley recall, which was handled swiftly and efficiently, preventing any harm to consumers. In contrast, the Peanut Corporation of America disaster, where delays and lack of communication led to widespread contamination and fatalities, serves as a stark reminder of the importance of speed in recall execution.

Regulatory compliance and customer trust hinge on the ability to execute recalls quickly and effectively.

Key Features:

-

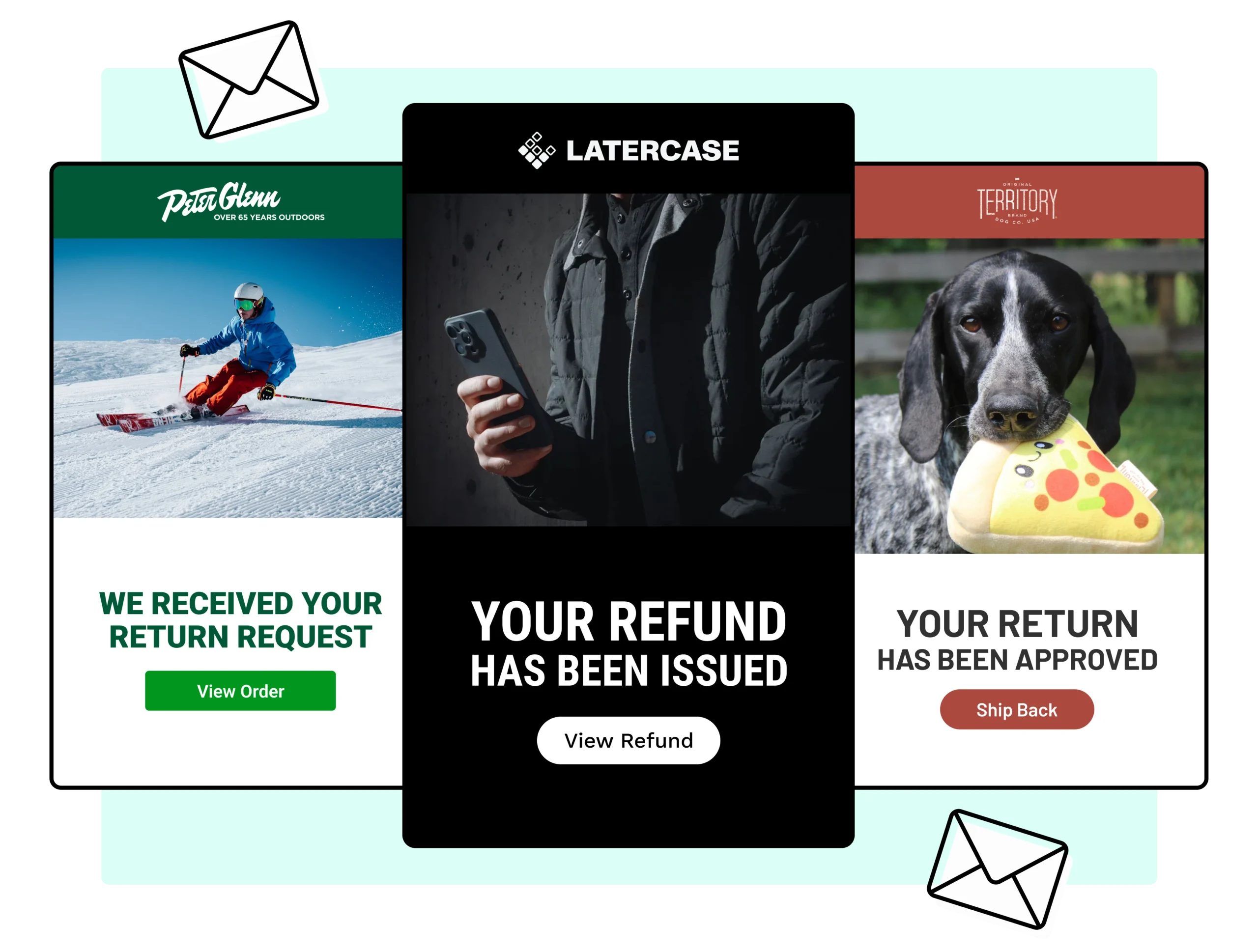

Automated Multichannel Communication:

-

Send recall alerts via email, SMS, and personalized notifications to inform customers promptly.

-

Utilize a centralized platform to ensure consistent messaging across all channels.

-

-

Real-Time Tracking and Reporting:

-

Monitor recall progress with real-time data and ensure affected customers take necessary actions.

-

Generate detailed reports to track compliance and measure recall effectiveness.

-

-

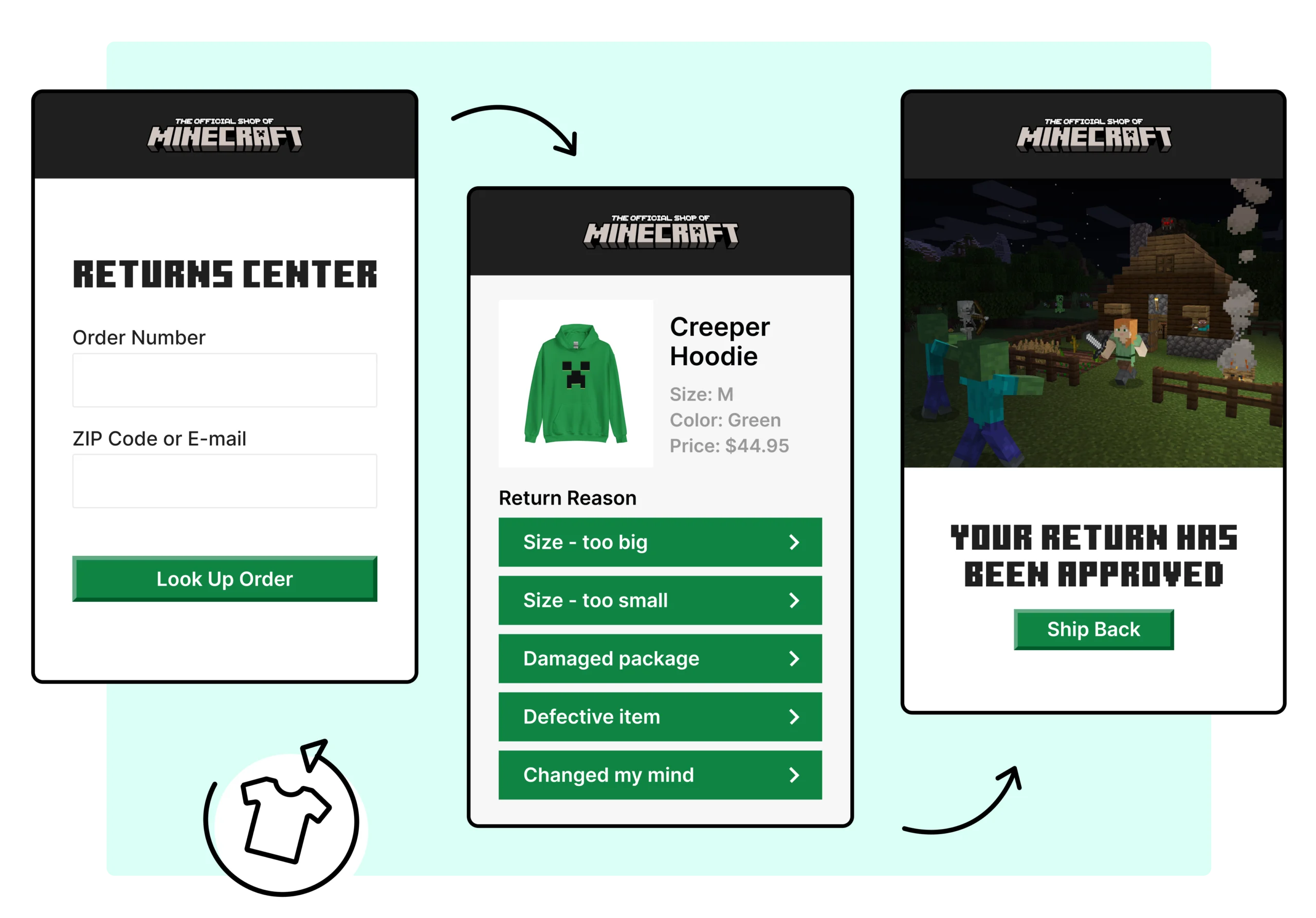

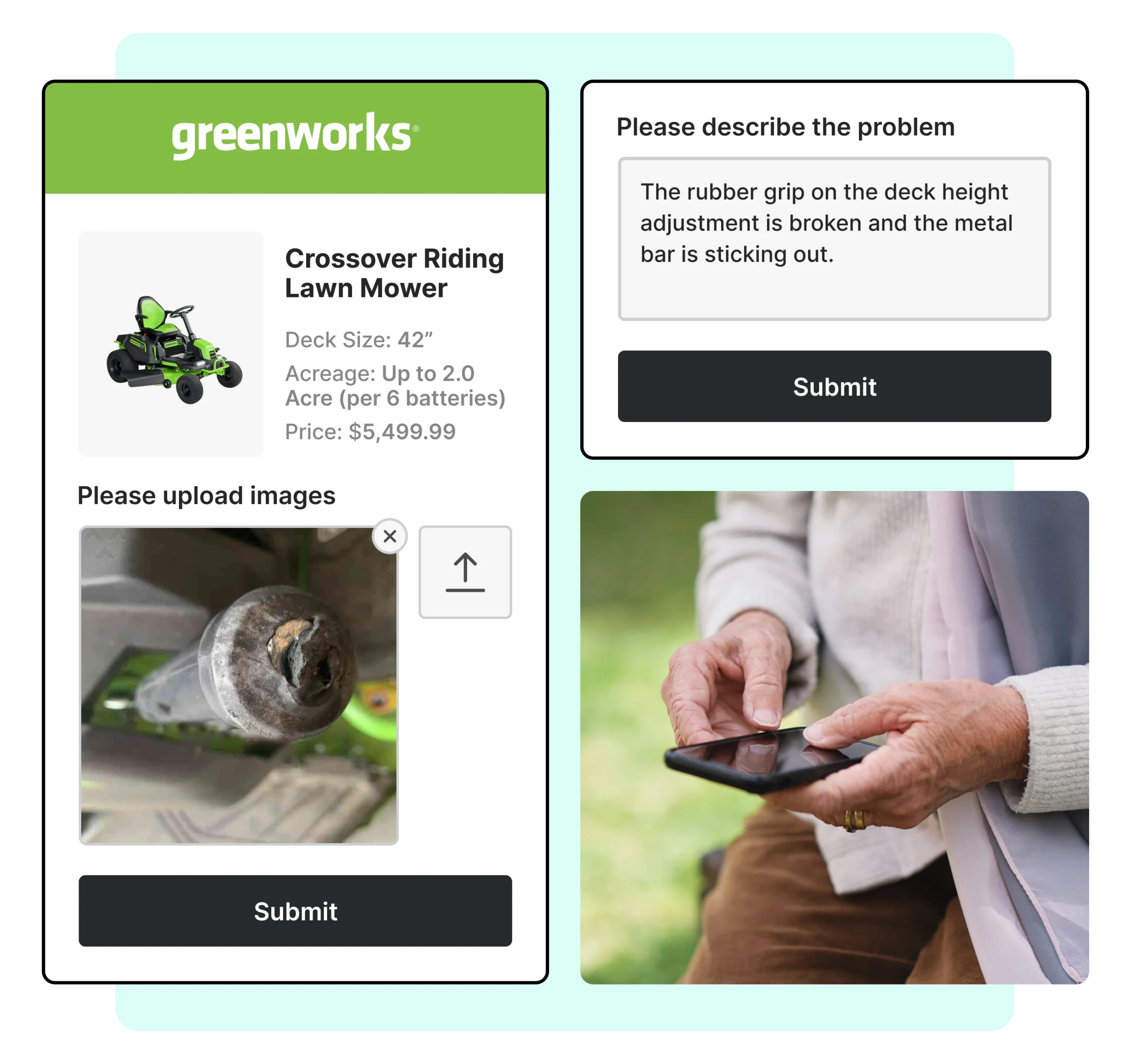

Customer Self-Service Portals:

-

Provide customers with a user-friendly platform to verify affected products and initiate returns or replacements effortlessly.

-

Offer clear guidance to streamline the recall process and minimize delays.

-

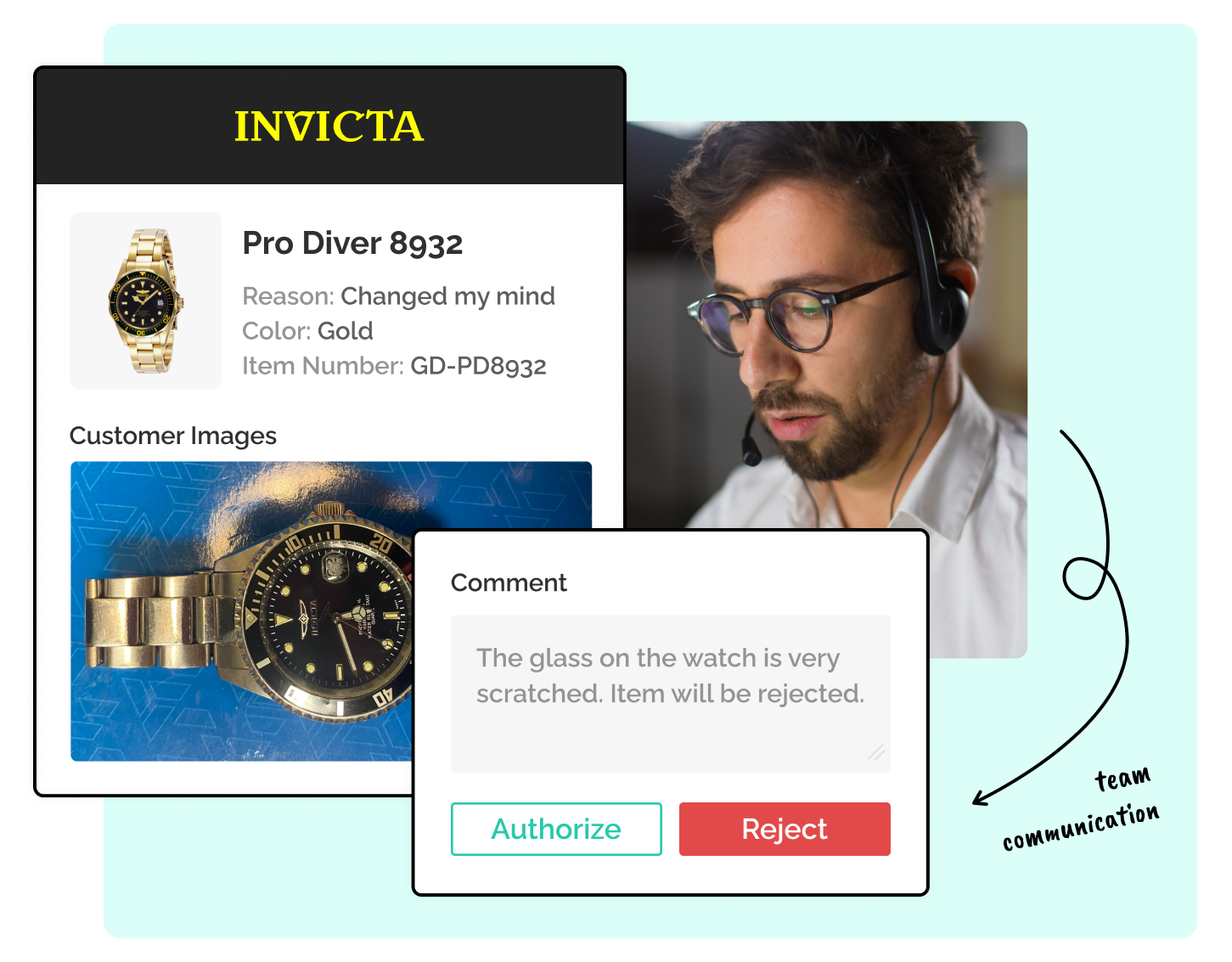

Managing Returned Products: Inspection, Sorting, and Value Recovery

Managing returned products is crucial in the return processes of the reverse logistics process. The process starts with return initiation and authorization, followed by a thorough assessment of the product’s condition. This assessment helps determine the next steps, such as repair, resale, recycling, or disposal. Centralized processing centers play a vital role in streamlining this process and ensuring consistency.

Sustainability also plays a key role in managing returned products. By categorizing returns and maximizing resource recovery, companies can minimize waste and contribute to environmental sustainability. Effective reverse logistics processes enhance customer satisfaction while supporting green initiatives and responsible business practices.

Key Features:

-

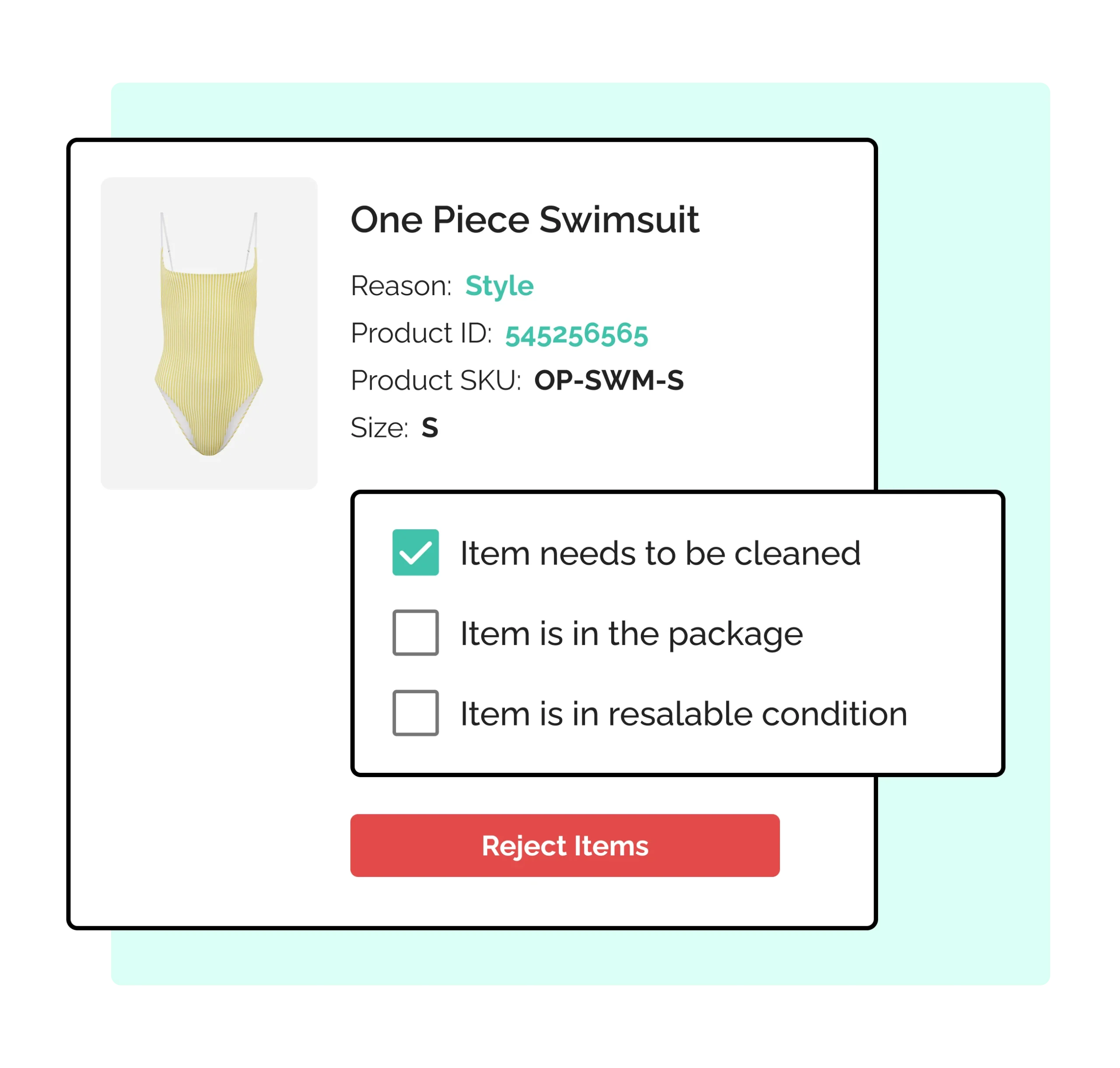

Define Quality Check Criteria:

-

Establish clear standards to ensure consistent and accurate product evaluations.

-

Enhance the quality of returned items eligible for resale or repurposing.

-

-

Collect Product Images and Customer Feedback:

-

Enable customers to submit images and detailed feedback during the return process.

-

Leverage insights to improve product quality and customer satisfaction.

-

-

Facilitate Warehouse Notes for Returns:

-

Equip warehouse staff with the ability to add notes during quality inspections.

-

Document essential details to streamline decision-making on restocking or disposal.

-

-

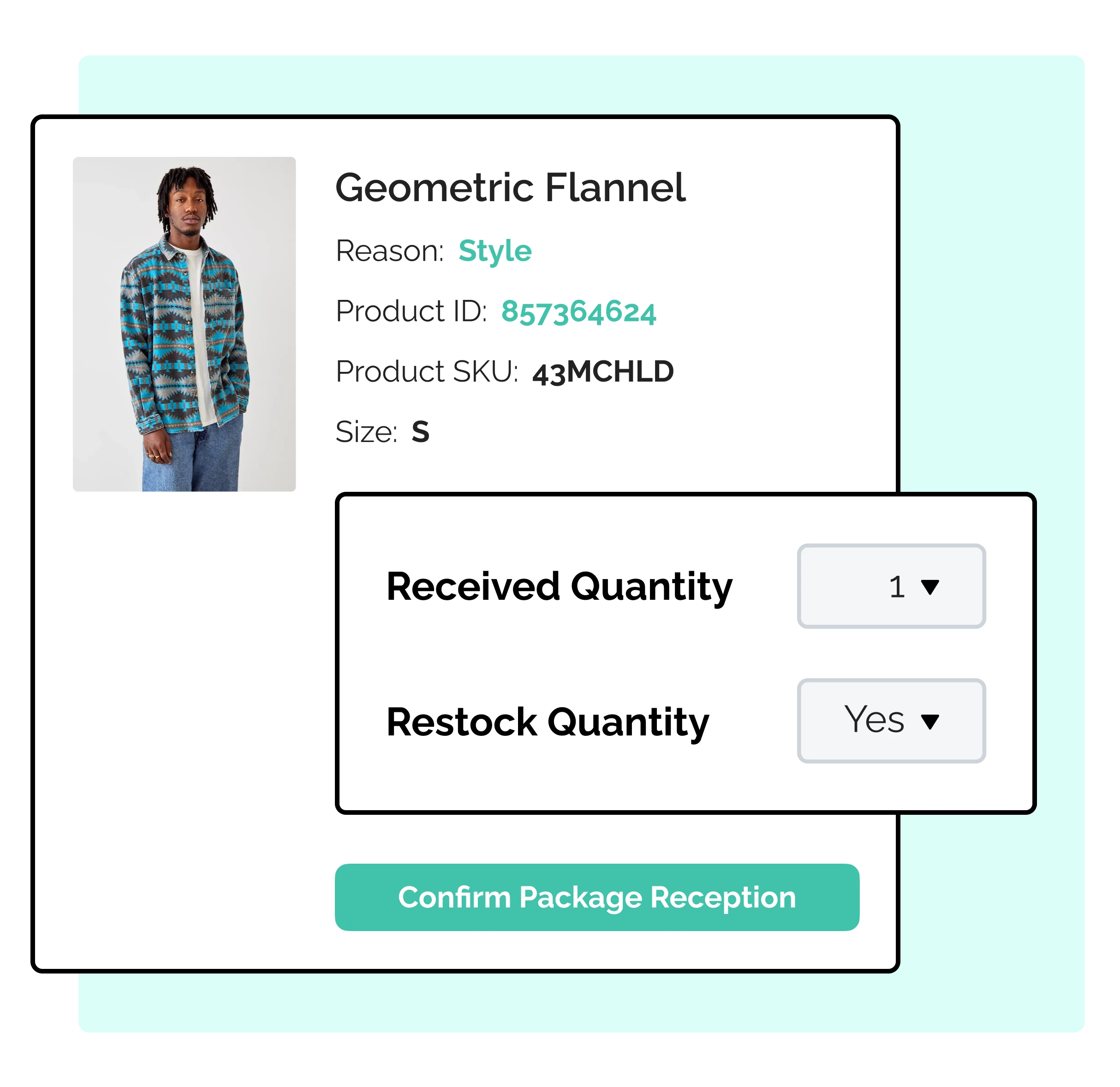

Optimize Inventory Management with Restocks:

-

Seamlessly reintegrate eligible products into inventory for quicker resale.

-

Reduce waste and maximize value recovery.

-

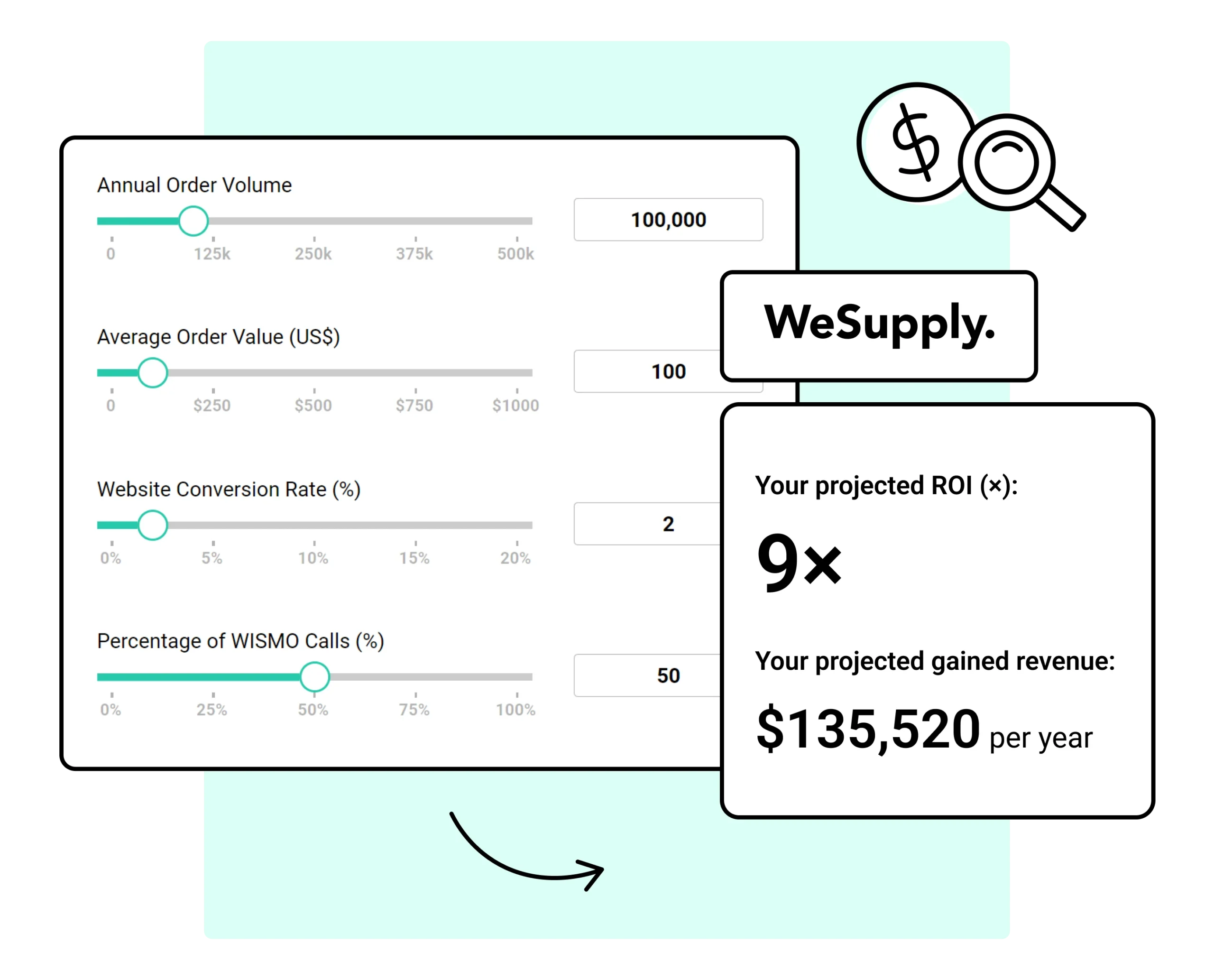

Elevate your returns process with WeSupply’s advanced tools for inspection and inventory management, transforming challenges into opportunities for efficiency, sustainability, and customer satisfaction.

Leveraging Technology: Automation, AI, and Smart Systems in Reverse Logistics

Technology is revolutionizing reverse logistics, increasing its efficiency and effectiveness. Robotic sorting systems and warehouse management systems (WMS) automate the handling of returned products, reducing manual labor and increasing accuracy. Artificial intelligence (AI) is crucial in making disposition decisions, directing each product to the most appropriate next step.

Returns management systems (RMS) offer end-to-end visibility, enabling companies to track and manage returns seamlessly.

Future trends like APIs, the Internet of Things (IoT), and predictive analytics will further enhance reverse logistics, helping businesses stay ahead of the curve and adapt to changing demands.

Key Features:

-

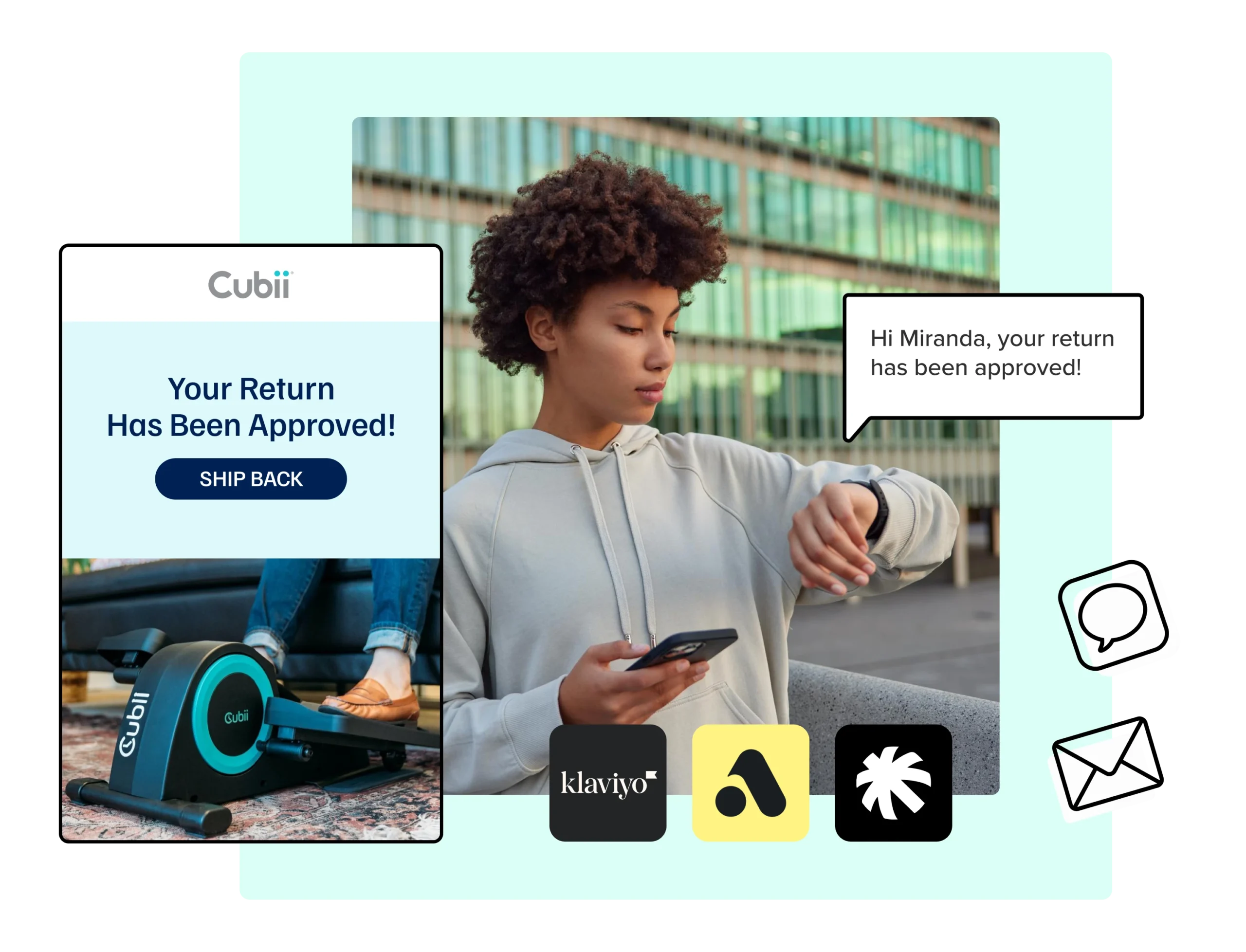

-

Simplifies returns with automated workflows, reducing manual intervention.

-

Offers real-time tracking and updates, ensuring transparency and customer trust.

-

-

AI-Powered Disposition Decisions:

-

Employs intelligent disposition tools to decide on product resale, recycling, or disposal.

-

Maximizes the value of returned items while minimizing waste.

-

-

Seamless Integration with APIs:

-

Integrates with existing systems via API connectivity for streamlined operations.

-

Syncs order and return data for enhanced visibility and control.

-

-

Predictive Analytics for Proactive Decision-Making:

-

Delivers insights on return patterns and customer behavior to inform future strategies.

-

Identifies trends to improve operational efficiency and customer satisfaction.

-

-

Self-Service Customer Portals:

-

Empowers customers to manage returns autonomously with user-friendly portals.

-

Enhances customer satisfaction by providing a hassle-free experience.

-

-

-

Reduces environmental impact with printerless QR code returns and in-store drop-off options.

-

Supports sustainable practices in reverse logistics.

-

Benefits of an Optimized Reverse Logistics Recall Process

Numerous benefits arise from an optimized reverse logistics process. Better inventory and asset recovery lead to cost savings, reducing the financial burden of recalls. Enhanced customer experience and competitive advantage are also significant benefits. Customers’ trust and loyalty strengthen when they know they can rely on a company to handle recalls efficiently.

An optimized process also enhances supply chain transparency and accountability, keeping all stakeholders informed and aligned. It supports sustainability and green initiatives, contributing to a closed-loop supply chain that minimizes waste and environmental impact by reusing and recycling resources.

Common Challenges and Risks in Reverse Logistics for Recalls

Despite its benefits, reverse logistics for recalls presents its own set of challenges. Managing large return volumes and coordinating returns across the supply chain can be daunting. A lack of visibility and control can result in inefficiencies and increased costs. The financial stakes are high, with U.S. retail returns amounting to $761 billion in 2021 alone.

Regulatory hurdles and environmental pressures further complicate the reverse logistics process. Companies must navigate a maze of regulations and ensure that returned products are disposed of responsibly to avoid legal repercussions and protect their reputation.

Strategies to Optimize Reverse Logistics for Product Recalls

A strategic approach is essential for optimizing reverse logistics for product recalls. Embracing data analytics and supply chain intelligence can provide valuable insights and improve decision-making. Adopting the 5 R’s of reverse logistics – returns, reselling, repairs, repackaging, and recycling – can help streamline the process and maximize resource recovery.

Integrating logistics with green initiatives fosters sustainable practices and contributes to a circular economy. Utilizing third-party logistics providers (3PL) can be a cost-effective solution for managing recalls.

Staying adaptable to technological advancements and regulatory changes helps future-proof operations, ensuring companies are prepared for any challenges.

Conclusion: Reverse Logistics as a Competitive Advantage in Crisis Management

In summary, reverse logistics is not just a necessary component of the supply chain; it serves as a strategic advantage in crisis management. Investing in effective reverse logistics processes allows companies to protect their profits, maintain customer trust, and enhance brand reputation. The benefits of reverse logistics extend beyond immediate cost savings, offering long-term advantages in customer loyalty and sustainability.

Proactive investment in reverse logistics is crucial for businesses to thrive in today’s competitive market. The future of product recalls is data-driven, fast, and sustainable. Companies embracing these principles will be well-positioned to turn potential crises into opportunities for growth and building trust.

Summary

Reverse logistics is a critical aspect of supply chain management, especially during product recalls. By defining reverse logistics and understanding its complexities, businesses can better prepare for and manage recalls efficiently. Effective reverse logistics processes protect profits, enhance customer satisfaction, and support sustainable practices.